Three Things to Consider in Electron Irradiation Testing

Posted date:November 02, 2023Last updated:November 02, 2023

NHV Corporation provides electron beam irradiation services in addition to manufacturing electron beam irradiation equipment.

Our irradiation service includes experimental irradiation and contracted processing that is used in the research and development of new products and in mass production studies prior to the installation of new equipment.

Now, we will introduce three points to consider when you decide to try electron beam testing for the first time.

①Purpose of Processing

The first thing that should be clarified is the purpose of electron beam irradiation processing. There are four effects of electron beam irradiation: cross-linking, graft polymerization, curing, and sterilization. For each of these effects, the irradiation conditions, such as the irradiation atmosphere and irradiation dose, are roughly determined, which is a key point for considering test conditions.

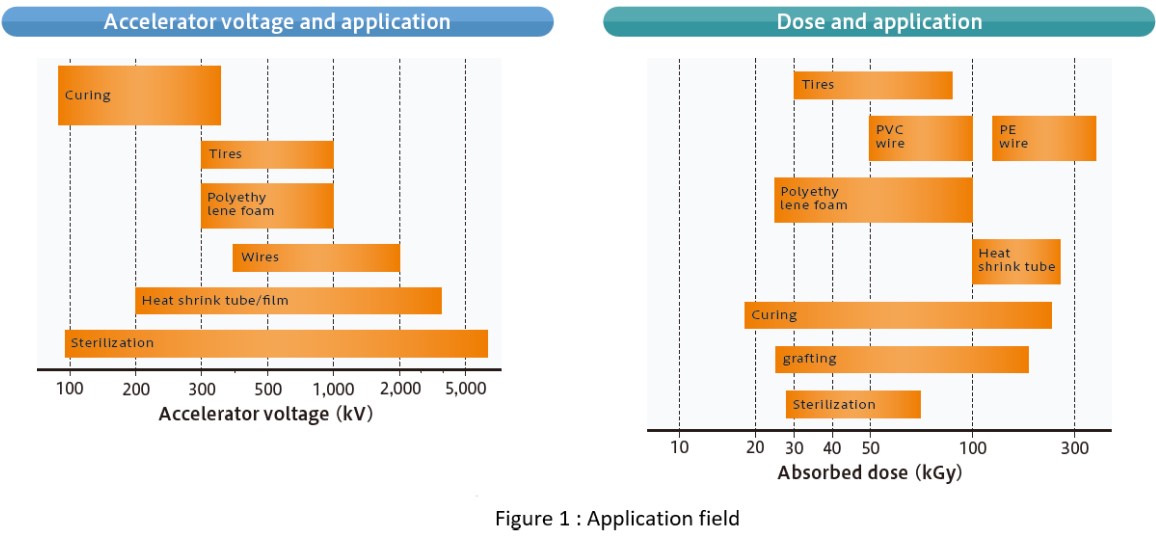

Figure 1 shows the regions of acceleration voltage and dose that are commonly applied in each application field.

Furthermore, in the case of crosslinking, the irradiation conditions will vary depending on whether you want to crosslink only the surface of the material or the entire thickness. In graft polymerization, the functional monomer to be used depends on the specific function (e.g., hydrophilicity, water repellency, moisture absorption/heat generation).

②Materials

The degree of influence exerted by an electron beam depends on the material.

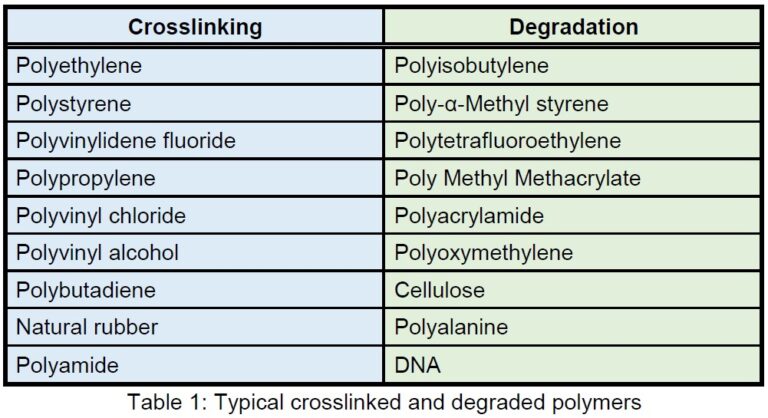

For example, in crosslinking, whether a polymer chain is easily crosslinked or degraded depends on the polymer structure.

Typical crosslinking type and degradation type polymers are shown in Table 1.

However, there are some polymers whose structure is not susceptible to electron irradiation, but the degree of influence of electron irradiation changes when heat is applied. A typical example is polytetrafluoroethylene (PTFE), which is a degradation type polymer at room temperature but is known to cross-link when heated to near its melting point of 340°C and irradiated.

The depth of penetration of electrons varies depending on the specific gravity of the material, which is an important factor in selecting the acceleration voltage of the electron beam.

③Size & Shape

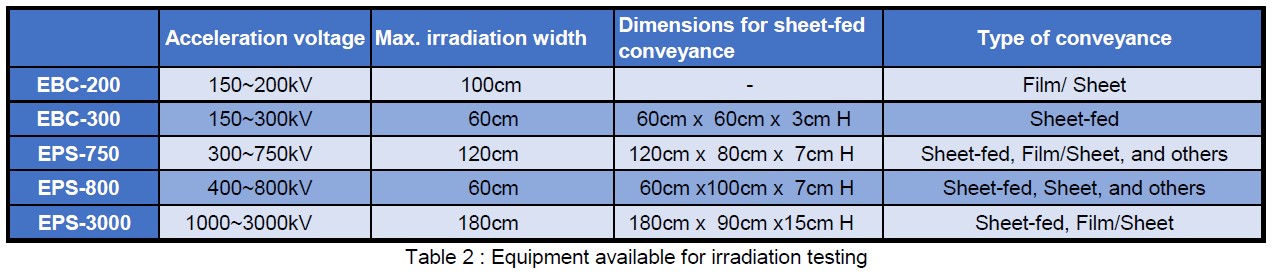

Table 2 shows a list of equipment specifications that can be used in irradiation tests. These are equipment capable of single-wafer processing and equipment for long film transport.

For example, the EBC-300 is suitable for single-wafer processing at an acceleration voltage of 300 kV or lower. The maximum material size is 60cm x 60cm square, and five A4 size sheets can be irradiated at once under the same conditions.

For roll processing, EBC-200 is suitable for polyethylene (specific gravity 0.9) with a film thickness of 50µm. For larger thicknesses, select the EPS-750 with a larger acceleration voltage.

We will propose the irradiation conditions and equipment to be used based on the processing purpose and the material to be irradiated.

Summary

We have introduced three important criteria when conducting electron irradiation tests: ①Purpose of processing, ②Material, and ③ Size & Shape.

When considering testing, please contact our staff with as much of this information as possible. For special materials and irradiation conditions, we will propose appropriate equipment and irradiation conditions based on our more than 40 years of experience and know-how.

[Inquiry]

NHV Corporation

Please inquire through the inquiry form.